JEZET Restoration Machines bv

Beatrixlaan 5

4645 HD PUTTE

The Netherlands

T +31(0)164606493

F +31(0)164606495

E info@jezet-

W www.jezet-

JEZET LEAFCASTING APPARATUSES with vacuum table possibilities TYPE AV

Starting in 1979 and after very thoroughly research, development and tests for several

years, JEZET has succeeded to manufacture a "LEAFCASTER", which meets all requirements

of the restorers concerning a proper wet leafcasting, more or less as a mass-

A restoration by leafcasting according to the old reliable professional skill, but using the latest techniques.

From a simple manually operated LEAFCASTER to multifunctional electric/pneumatic controlled machines.

SPECIFIC ADVANTAGES OF THE JEZET LEAFCASTERS

The JEZET-

Big work-

Divided sheet forming-

Mobile, Compact built, Plug and play ready machine and moderate in total weight

Simple and -

Made of all inert materials Aluminium, Polyethylene, Silicone foam, Teflon, Stainless

steel -

Water reservoir is also scrubber or traptank

Electric and Pneumatic safety devices according safety rules of each country

Low water-

High quality and production, 8 sheets A4 or one unfolded newspaper every 5 minutes.

Special requests -

No maintenance only cleaning -

Above actually LEAFCASTING the more JEZET LEAFCASTERS can be used as LEAF-

DEACIDIFYING as LC with the documents completely in and under

deacidifying-

as VT on the hole document with

a spray-

WASHING as LC in water with detergent for example Calcium hydroxide or solvent or wash out detergents and/or solvents, Vinegar acid

BLEACHING as LC in water with Ammonia, Chloramines T,

Chloride of lime, Calcium-

NEUTRALISING as LC in water with Sodium thiosulfate or Hyposulfite to stop further bleaching or neutralization.

LOCAL RINSING as VT for local cleaning and rinsing with water, acids, basics, solvents Sodium carbonate, Kerosene

DECOLORIZE as VT with Phenyl amine

DISSOLVE as VT with Amyl acetate, Ethanol, Methanol, Tetra, Pyridine, Toluene

DEGREASE as VT with Acetone, Pyridine, Carbon Tetrachloride

TAPE REMOVAL as VT with Acetone, Benzene, Pyridine

DESINFECTING as LC in liquid with disinfectants Sodium-

as VT with liquid-

SPOT FIBERING as VT Pouring on, spot Leaf Casting or filling up holes in parchment or fibrous textiles, like felt.

SIZING as LC glue together with water and fibers Gelatin, Methylcellulose, Collagene

as VT sizing with spray gun.

VACUUM-

JEZET LEAFCASTER AVFwSvPeME-

Casting area (8 X A4 or unfolded newspaper)

Area height

Outside measures

Weight

Electricity consumption

Water outlet

Air outlet

Noise level

Colour

850 x 600 mm

800 mm

H x W x D = 1300 x 950 x 800 mm

approximately 60 kg

1.500 Watt maximum 230V – 50hz 1 Phase

Ø 32 mm flexible synthetic hose 3 meters

Ø 75 mm flexible synthetic hose 5 meters

with operating suction device 60 dB. otherwise 45 dB

Silver and Black

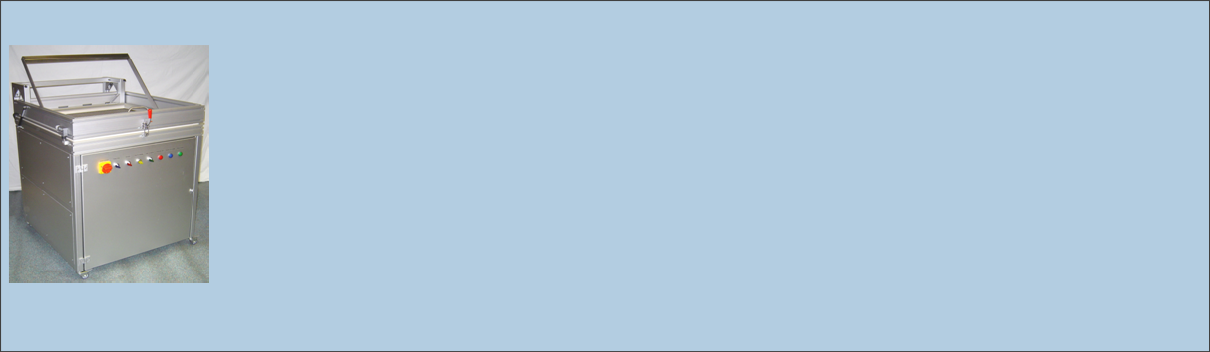

JEZET LEAFCASTER AVFwSvPeME-

Casting area (12 X A4)

Area height

Outside measures

Weight

Electricity consumption

Water outlet

Air outlet

Noise level

Colour

950 x 850 mm

800 mm

H x W x D = 1300 x 1050 x 1000 mm

approximately 75 kg

1.500 Watt maximum 230V – 50hz 1 Phase

Ø 32 mm flexible synthetic hose 3 meters

Ø 75 mm flexible synthetic hose 5 meters

with operating suction device 60 dB. otherwise 45 dB

Silver and Black

JEZET LEAFCASTER AVFwSvPePE-

Casting area (8 X A4 or unfolded newspaper)

Area height

Outside measures

Weight

Electricity consumption

Compressed Air consumption

Air connection

Water outlet

Air outlet

Noise level

Colour

850 x 600 mm

800 mm

H x W x D = 1300 x 1050 x 1000 mm

approximately 90 kg

1.500 Watt maximum 230V – 50hz 1 Phase

50 litres p/m maximum 8 Bar flexible

¼" hose with quick release connection

Ø 32 mm flexible synthetic hose 3 meters

Ø 75 mm flexible synthetic hose 5 meters

with operating suction device 60 dB. otherwise 45 dB

Silver and Black

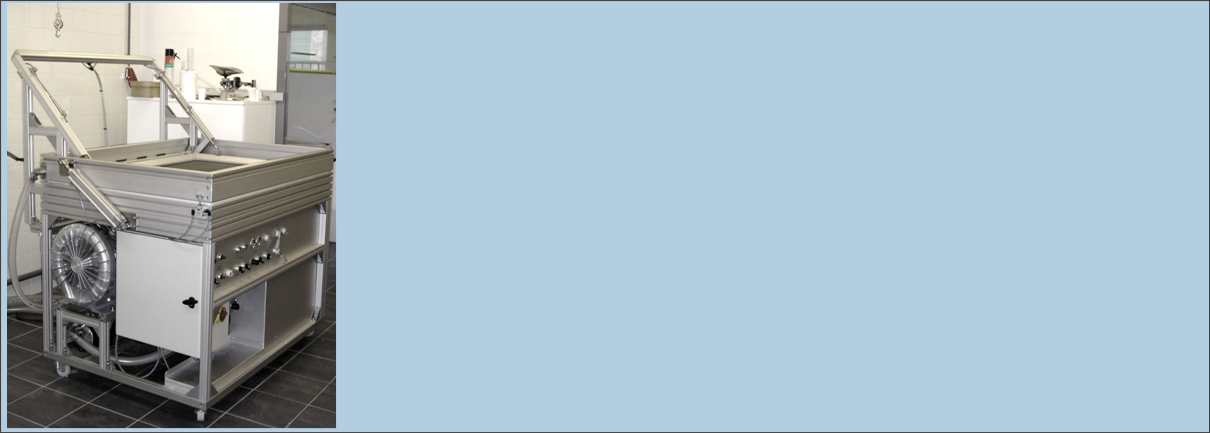

JEZET LEAFCASTER MULTIRESTOR® 14-

MULTIFUNCTIONAL RESTORER is capable for the total of 14 different treatments on/of paper and consists of;

LIQUIDS TREATMENT BASIN with upper treatment tank + bottom treatment tank + 2 parts support grid

SUPPORT FRAME -

JEZET MEDIUM PRESSURE SUCTION TABLE

JEZET MOISTENING UNIT with MOISTENING or CLIMATE DOME (removable) + HYGROSTAT + HUMYDIFYER

JEZET LEAFCASTING UNIT with SUPPORT SCREENS, CASTING SCREENS, HOLD DOWN GRID, LEAF CASTINGSURFACE ELECTRIC CONROLS + CONTROL PANEL ECP.

Usable Surface for/as Work; Suction, Leafcasting, Rinsing etc.

Working height

Outside dimensions

Electrical connection

Maximum power consumption

Compressed Air consumption

Air connection

Water connection

Water consumption

Drain

Exhaust connection

Noise level

Total weight

Colour

1100 x 800 mm

900 mm

H x W x D = 1200 x 1220 x 1000 mm

Euro connector with flexible cable of 10 m single phase -

2,2 k Watt 16 Ampere 230 Volt – 50 Hz

50 litres p/m maximum 10 Bar

flexible ¼" hose with quick release connection

quick release coupling and flexible hose Ø 13 mm of 6 meters

about 150 litres per week

flexible hose of Ø 32 mm 5 meters

flexible hose of Ø 75 mm 10 meters

during suction maximum noise level of 60 dB otherwise 45 dB

approximately 180 kg

Silver and black

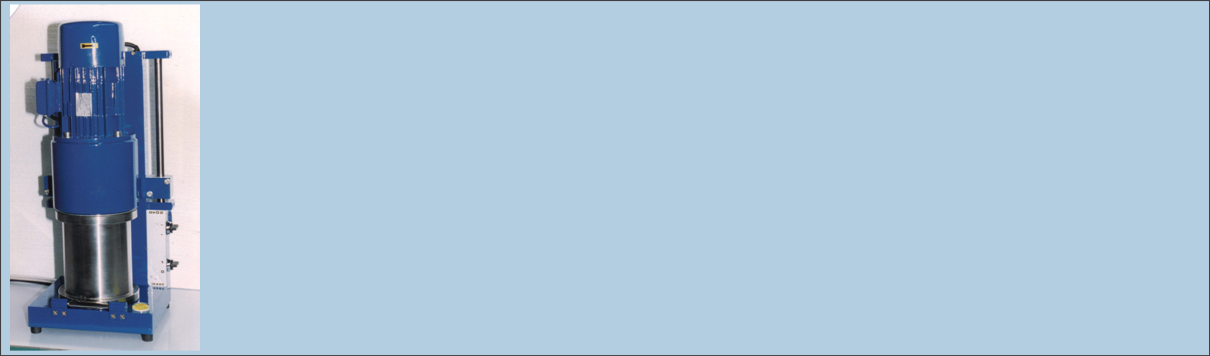

JEZET PAPER PULP DISINTEGRATORS

For disintegration of cellulose pulp, according to the international standard V/4/61

of the union of Cellulose-

ADVANTAGES OF THE JEZET PULP-

Fibres are not warmed up like other type of mostly grinding processes.

Fibres will not been cut (like in a blender) but separated by the shearing effect of this particular process.

Made of all inert materials Aluminium, Polyethylene, Silicone foam, Teflon, Stainless steel

Mobile, Compact built, Plug and play ready machine and moderate in total weight

Simple and -

Electric and Pneumatic safety devices according safety rules of each country

Low noise level

Small or large quantity of pulp 10 up to 580 grams a day.

No maintenance only cleaning -

NO PHOTO IN CONNECTION WITH COMPETITION

NEW

JEZET PAPER PULP DISINTEGRATOR OVE-

Capacity 5 TO 15 % AD FIBERS

Working height

Materials

Outside Dimensions

Electric consumption

Speed regulation of the Shaft and propeller

Weight

Noise level

Colour

20-

table height

Aluminium

320 x 400 x height 700 mm

0,75 kW, 230 Volts, Single phase, 50 Hz

100 to 3000 revolutions per minute

28 kg

less than 40 dB

SILVER ANODISED

JEZET PAPER PULP DISINTEGRATOR OVE-

The stanchion is further executed ON/OFF LEVER-

The UP/DOWN LEVER-

Capacity

Working height

Materials

Outside Dimensions

Electric consumption

Weight

Noise level

Colour

10-

table height

Aluminium and Stainless steel

320 x 400 x height 700 mm

0,75 – 1.2 kW, 230 Volts, Single phase, 50 Hz

31 kg

less than 40 dB

SILVER ANODISED

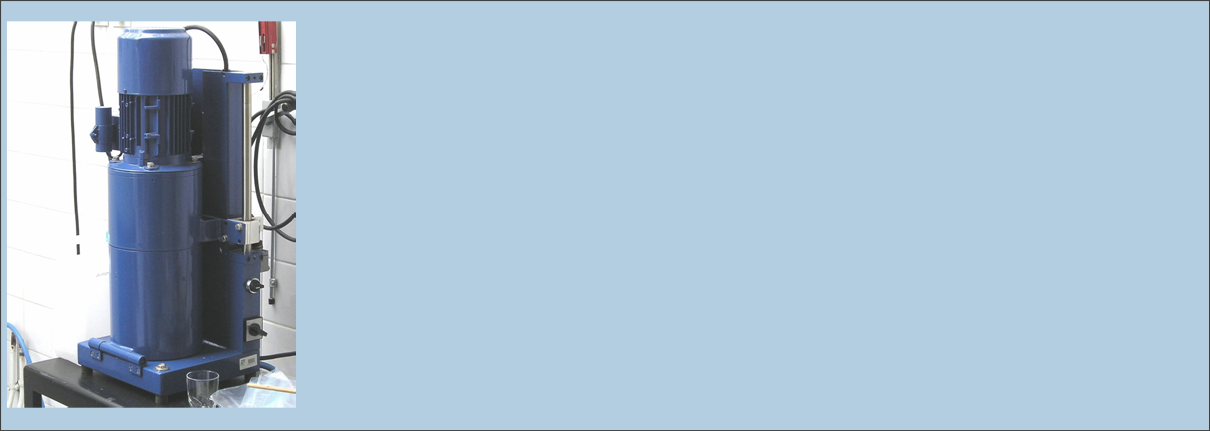

JEZET PAPER PULP DISINTEGRATOR OVP-

The stanchion is further executed ON/OFF LEVER-

The UP/DOWN LEVER-

Capacity

Working height

Materials

Outside Dimensions

Electric consumption

Compressed air consumption

Weight

Noise level

Colour

10-

table height

Aluminium and Stainless steel

320 x 400 x height 700 mm

0,75 – 1.2 kW, 230 Volts, Single phase, 50 Hz

max. 25 litres per min. by 6 Bar./87 psi

45 kg

less than 40 dB

blue powder coated

NECESSARY VERY SMALL COMPRESSOR FOR THE DISINTEGRATOR WITH A SUPPLY OF COMPRESSED AIR OF ABOUT 1,1 kW 220 V 50 Hz and an OUTPUT OF 100 litres/minute at 9,0 bars MAX.

JEZET VANISHED SURFACE CALCULATOR PUCAL-

In principle the calculator measures the existing part and two conditions of the document to be leafcasted:

a.) Definition of the estimated size of the original document with an additional 20 mm surrounding margin

b.) Measurement of the thickness of the part of the paper in best condition

c.) Measurement of the surface of the holes in the paper, gaps and the surrounding margin

Together gives a volume of fill, directly translated by a integrated computer into the quantity of grams of dry paper pulp or millilitres of pulp with a fixed mixture of fibres and water. Three possibilities for output are usable: digital reading of grams of paper pulp or a hard copy or a electric pulse to a paper pulp dosing system.

THE CALCULATOR includes: A plateau and a vertical column of rectangles anodized aluminium profiles, together a rigid, light and mobile form. A multi LED lamp 12 W to equal and uniformly lighting. A digital camera is mounted mobile on the column. The camera height corresponds with the measurement surface. The work surface is executed with a spectral green colour (minimize the measurements faults of the different colours of paper and inks). Control cabinet with switches, buttons, meters, regulators, etc.

The dimensions of the spectral Green work surface .(Five A4 format simultaneously)

The measurement of the thickness of the document is without contact and effective

Working height

Outside Dimensions

Electric consumption

Compressed air consumption

Weight

Noise level

Colour

maximum of 790 x 580 mm

0,0 -

table height

L 1000 x P 840 x H 1100 mm

0,250 kW, 230 Volts, Single phase, 50 Hz

max. 25 litres per min. by 6 Bar./87 psi

less than 40 dB

Silver / Green

Advantages

Without recourse of an external computer to be use by everyone without special knowledge,

Simple and -

Quick, minimum actions, different readings and digital camera.

Mobile, Compact built, Plug and play ready machine and moderate in total weight 15 kg.

Made of all inert materials Aluminium, Polyethylene, Silicone foam, Teflon, Stainless steel

Five A4 format simultaneously or A format A4

Green surface (minimize the faults of measurements of different colours of paper and inks)

Measurement of the thickness without contact.

Lack of weight measurement

Connectable with a pulp dosing system

Special requests -

No maintenance only cleaning -

NO PHOTO IN CONNECTION WITH COMPETITION

NEW

JEZET PAPER PULP DOSING SYSTEM PUDOS-

Use integrated with a JEZET Leafcaster or Multirestor or be used separately with other machines. The dosing system is composed of: a support of anodized aluminium profiles on 4 castors with brakes and a place for a disintegrator. A storage tank executed in black polyethylene of 10 litres with concentrated pulp of the disintegrator with an agitator to prevent the separation of the fibres. A reservoir of white polyethylene of 60 litres and a transparent Polycarbonate front with the preset mixture with the chosen concentration. Coupled with a permanent circulation system, maintaining the mixture constantly on the right concentration between the water and the pulp.

Executed with transparent pipes, circulation pump, valves, maximum and minimum level, security controls and control of concentration.

Linear dosing valve for the injection of the exact amount, a simple adjustment device in the volume of the right amount of pulp. Connection of supply water with valves and meters. Control cabinet with switches, buttons, meters, regulators, etc.

During the injection of the mixture of the pulp, additional water is added to dilute the mixture still more, to get a better casting without lumps of fibre.

Working height

Outside Dimensions

Electric consumption

Compressed air consumption

Noise level

Colour

table height

L 800 x P 400 x H 1200 mm

0,50 kW, 230 Volts, Single phase, 50 Hz

max. 25 litres per min. by 6 Bar./87 psi

less than 40 dB

Silver / White

Advantages

Simple and -

Mobile, Compact built, Plug and play ready machine and moderate in total weight 37 kg.

Made of all inert materials Aluminium, Polyethylene, Polycarbonate, Teflon, Stainless steel

No computer or fragile electronic system

Components transparent (pollution control)

Special requests -

No maintenance only cleaning -